Flange-

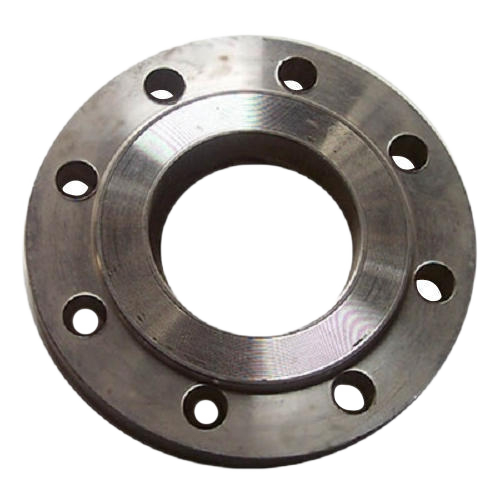

A flange is a mechanical component used to connect two sections of pipes, valves, or equipment in a system. It is a flat, circular disc with evenly spaced bolt holes around its circumference. Type of Flanges are commonly made from materials like carbon steel, stainless steel, or other alloy materials, depending on the application and requirements.

The primary purpose of a flange is to provide a strong and secure joint between two components, ensuring a leak-proof connection. When two flanges are bolted together with gaskets in between, they create a tight seal that prevents fluids or gases from escaping or entering the system. This makes flanges essential in various industries, including oil and gas, petrochemical, water treatment, and more.

Flanges come in different types, such as welding neck flanges, slip-on flanges, socket weld flanges, blind flanges, and threaded flanges, among others. Each type of flange is designed for specific applications and is selected based on factors like pressure, temperature, and compatibility with the pipeline or equipment.

Additionally, flanges are often categorized by their standard specifications, such as ANSI (American National Standards Institute), ASME (American Society of Mechanical Engineers), DIN (Deutsches Institut für Normung), and others. These standards ensure that flanges manufactured by different companies can interconnect seamlessly and safely.

Overall, flanges play a crucial role in various industrial applications, allowing for easy maintenance, assembly, and disassembly of pipelines and equipment while maintaining the integrity of the system.

Type of flange-

There are several types of flanges, each designed for specific applications and requirements. Some of the common types of flanges include:

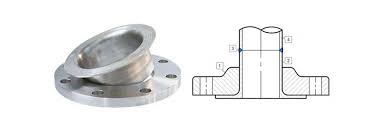

Weld Neck Flange:

This type of flange has a long tapered neck that is welded to the pipe, providing a strong and permanent connection. It is commonly used in high-pressure and high-temperature applications

Slip-On Flange:

A slip-on flange has a flat, slightly larger diameter than the pipe it is being connected to. It is slipped over the pipe end and then fillet-welded in place. These flanges are easier to align and are often used for low-pressure applications.

- read more-

- How to make a flange

- Details of flange

- Type of Gasket

Socket Weld Flange:

Socket weld flanges have a socket-like recess that fits over the pipe, and then the pipe is fillet-welded to the flange. They are suitable for smaller pipe sizes and high-pressure applications.

Blind Flange:

Blind flanges are solid discs used to close the end of a pipe or valve. They are commonly used to terminate the end of a pipeline or for inspection purposes

Threaded Flange:

Threaded flanges have internal threads that match the external threads of a pipe. They are commonly used for low-pressure applications and where welding is not feasible.

Lap Joint Flange:

A lap joint flange is typically used with a lap joint stub end. The flange has a flat face, and the stub end has a lap joint ring. The two components are bolted together, allowing for easy alignment and dismantling.

Slip-On Ring Flange:

This type of flange is used when facing constraints or when alignment is challenging. It features a rotating ring that can be easily aligned with the matching flange during installation.

Orifice Flange:

Orifice flanges are used in systems where flow measurement or flow restriction is required. They have a small orifice bore that can accommodate orifice plates for accurate flow measurement.

Spectacle Blind Flange:

A spectacle blind flange is a combination of a blind flange and a spacer ring. It is used to isolate sections of a pipeline or equipment during maintenance or shutdown.

Expander Flange:

- An expander flange is used to increase the pipe’s size at the flange connection. It allows for the transition between two different pipe sizes.

These are just some of the most common types of flanges used in various industries. Each type has its specific advantages and applications, and the choice of flange depends on factors like pressure, temperature, pipe size, and the specific needs of the system.

vurcazkircazpatliycaz.Xu1s62JETCuq