Introduction

Nuts are an essential component in various industries, including construction, automotive, plumbing, and DIY projects. Choosing the right type of nuts is crucial for ensuring strong and secure fastenings. In this guide, we will explore the different types of nuts, their applications, and how to select the right one for your needs.

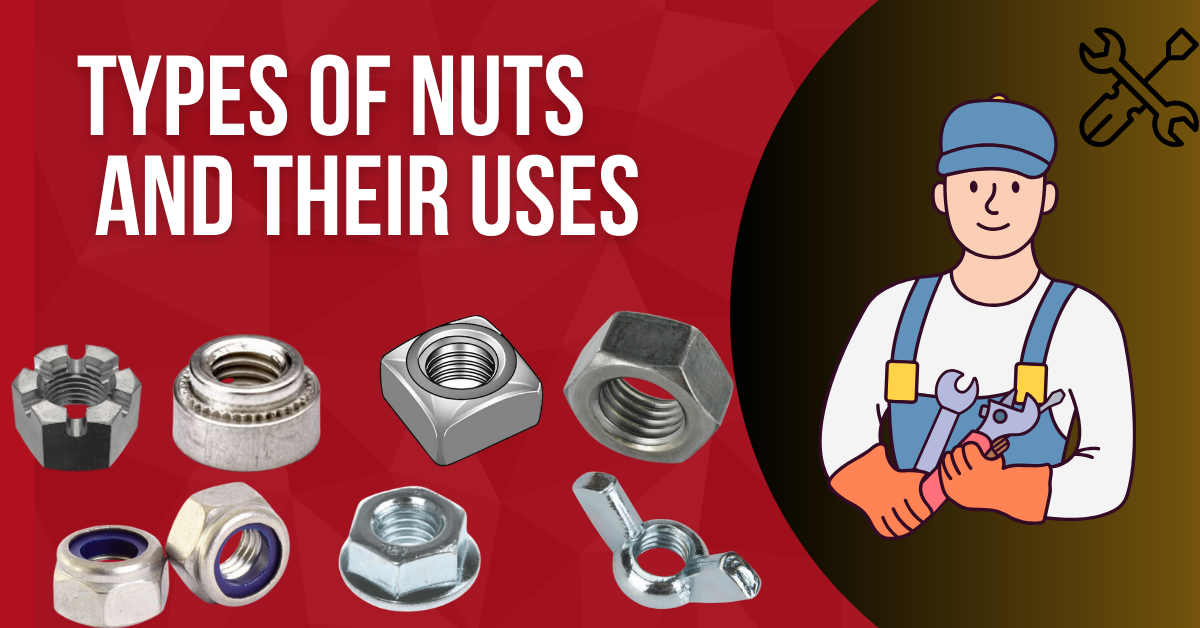

Types of Nuts and Their Uses

1. Hex Nuts

Description: The most common type of nut, featuring six sides for easy tightening with a wrench.

Uses: Used in construction, machinery, and automotive industries.

2. Lock Nuts

Description: Designed to prevent loosening due to vibration and torque. Types:

- Nylon Insert Lock Nut: Has a nylon ring to prevent loosening.

- Jam Nut: A thinner nut used as a locking mechanism.

- All-Metal Lock Nut: Made from metal with a deformed thread. Uses: Ideal for machines, vehicles, and vibrating equipment.

3. Wing Nuts

Description: Features two wing-like projections for hand tightening without tools. Uses: Common in applications requiring frequent adjustments, such as furniture and clamps.

4. Cap Nuts (Acorn Nuts)

Description: A nut with a domed top to cover exposed bolt threads for safety and aesthetics. Uses: Used in decorative finishes and to prevent injuries from sharp bolt ends.

5. Flange Nuts

Description: Has a built-in washer to distribute load evenly and prevent loosening. Uses: Ideal for automotive applications and machinery.

6. T-Nuts

Description: T-shaped nuts used to create strong anchoring points in wood and metal. Uses: Commonly used in furniture assembly and metalworking.

7. Square Nuts

Description: Features a four-sided design for greater surface contact and increased resistance to loosening. Uses: Used in woodworking, railroad construction, and heavy-duty applications.

- read more-

- Gate Valve,NRV & Y Strainer Size Chart

- Pipe ID, OD, CF, and Thickness Table Format

- ISA Angle Sizes in India: Comprehensive Details and Guide

8. Coupling Nuts

Description: A long, cylindrical nut used to connect two threaded rods or bolts. Uses: Frequently used in construction and plumbing.

9. Castle Nuts

Description: A nut with notches designed for use with a cotter pin to secure it in place. Uses: Found in automotive and aerospace applications.

10. Slotted Nuts

Description: Similar to castle nuts but with straight slots. Uses: Used in high-load applications where safety is crucial.

11. Self-Clinching Nuts

Description: Designed to be embedded into thin metal sheets for a permanent hold. Uses: Used in electronics, enclosures, and sheet metal fabrications.

12. Insert Nuts

Description: Has internal threads and is designed to be inserted into wood, plastic, or soft materials. Uses: Commonly used in furniture assembly.

Step-by-Step Guide to Choosing the Right Nut

Step 1: Determine the Application

- Identify whether the nut is for structural, decorative, or mechanical use.

- Consider the load and environmental conditions (e.g., high vibration, corrosion exposure).

Step 2: Choose the Material

- Steel: strong and durable; ideal for most applications.

- Stainless steel: corrosion-resistant; best for outdoor or moisture-prone environments.

- Brass: rust-resistant and decorative.

- Aluminum: lightweight and corrosion-resistant.

- Nylon: Used in locking mechanisms or electrical insulation.

Step 3: Select the Right Thread Type

- Coarse Thread (UNC): More resistant to stripping; used in general applications.

- Fine Thread (UNF): Provides a tighter fit and greater strength.

Step 4: Consider Special Features

- Locking mechanisms for vibration resistance.

- Decorative finish if aesthetics matter.

- Load-bearing capabilities.

Step 5: Match with the Correct Bolt

- Ensure the nut size and thread match the corresponding bolt or screw.

- Check for compatibility with washers and spacers if needed.

Conclusion

Choosing the right type of nut is essential for achieving secure and durable fastening in any project. By considering factors such as application, material, thread type, and special features, you can select the ideal nut for your needs. Whether you’re working in construction, automotive, or DIY projects, this guide provides you with the essential knowledge to make the best choice.