Introduction

Types of threads are the backbone of mechanical engineering, piping, and manufacturing. Whether you are tightening a bolt, connecting a water pipe, or designing a heavy machine screw, threads are everywhere. They provide fastening, sealing, and motion transfer across industries.

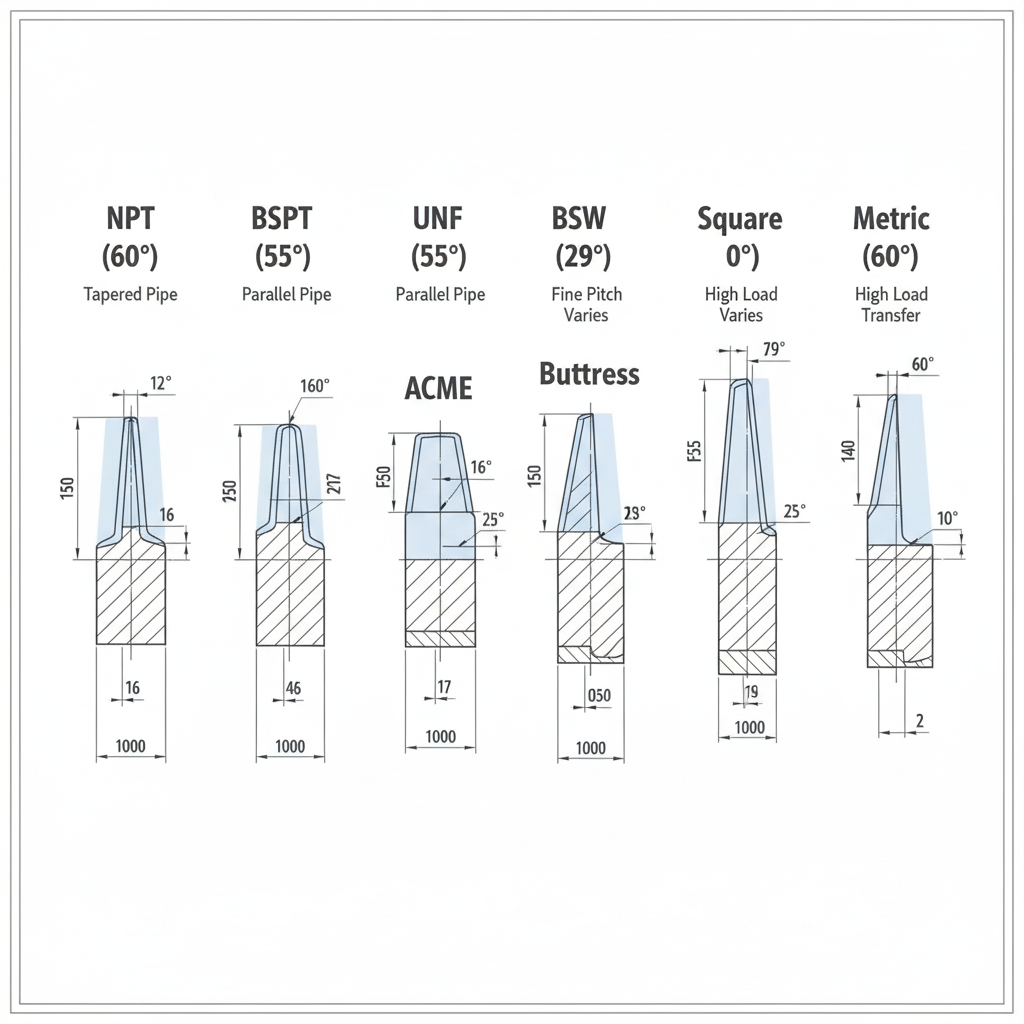

Different types of threads have been developed over time to meet specific needs. For example, NPT (National Pipe Tapered) is commonly used in plumbing and oil pipelines, while BSPT (British Standard Pipe Tapered) is standard in Europe and Asia. Aerospace industries prefer UNF threads, while heavy machinery relies on ACME threads for strength and power transmission.

This guide covers all major types of threads—their design, angles, pitch, standards, and uses—to help you select the right one for your project.

The Basics of Threads—

A thread is a helical groove cut into a cylinder (external threads) or a hole (internal threads). Its primary functions are:

- Fastening—bolts, screws, and nuts.

- Sealing—pipe fittings under pressure.

- Power transmission – lead screws, jacks, vises.

Key Terminologies

- Thread Angle—the included angle between the flanks.

- Pitch – distance between two successive crests.

- Lead—the distance a screw moves forward in one revolution.

- TPI (Threads per Inch)—used in imperial threads.

- Crest—top of the thread.

- Root – bottom of the thread.

2. Historical Development of Thread Standards

Threads date back to the 3rd century BC, when Archimedes designed the Archimedes screw for lifting water.

In the 1800s, as industrialization grew, different countries developed their own thread systems:

- 1841 – Sir Joseph Whitworth introduced the first standardized thread system in Britain (BSW).

- 1864 – William Sellers introduced the Unified thread form (60° angle) in the U.S.

- 20th Century – ISO introduced the metric thread system to unify global standards.

Today, threads are standardized by ANSI, ISO, DIN, BS, and JIS depending on the region.

3. Major Types of Threads

Now let’s explore the most important thread types in detail.

3.1 NPT (National Pipe Tapered Thread)

- Standard: ANSI/ASME B1.20.1

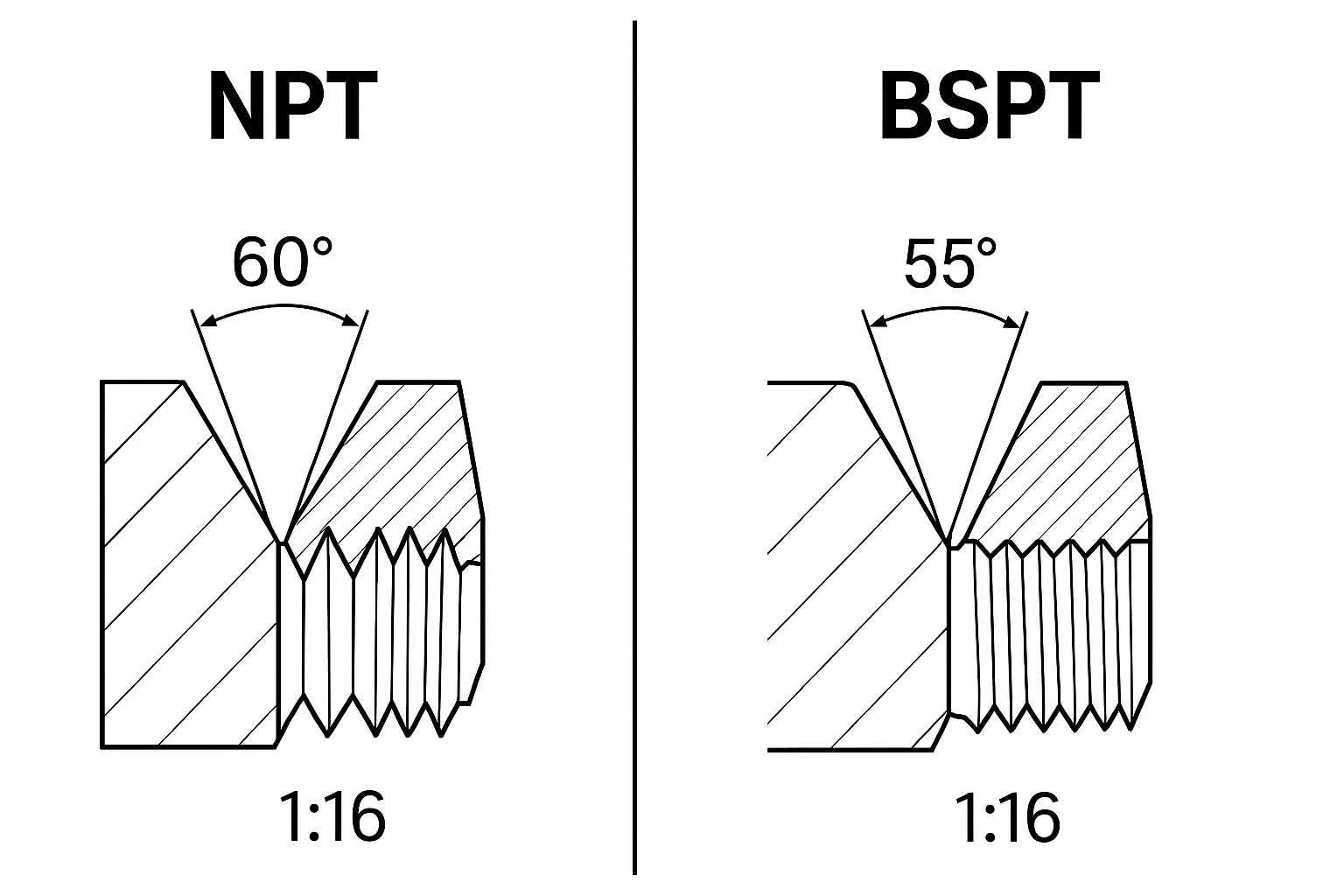

- Angle: 60°

- Taper: 1:16

- Crest/Root: Flat

- Sealing: Requires sealant (Teflon tape, paste)

Applications:

- Plumbing and piping

- Oil & gas pipelines

- Firefighting systems

3.2 BSPT (British Standard Pipe Tapered)

- Standard: BS 21 / ISO 7

- Angle: 55°

- Form: Whitworth rounded profile

- Taper: 1:16

Applications:

- Water and steam pipelines

- Fire hydrants and pumps

- Gas piping

Read more—

- MS Plate Weight – Formula, Calculation & Chart

- Pipe Thickness Formula—Explained (With Example) | पाइप की मोटाई का फॉर्मूला हिंदी में

- Type of nut

3.3 BSPP (British Standard Pipe Parallel)

- Standard: ISO 228

- Angle: 55°

- Type: Straight (parallel)

- Sealing: Requires washer or O-ring

Applications:

- Hydraulic systems

- Pneumatic fittings

- Low-pressure water lines

3.4 UNF (Unified National Fine Thread)

- Standard: ANSI/ASME B1.1

- Angle: 60°

- Pitch: Fine, higher TPI than UNC

- Strength: High due to more engaged threads

Applications:

- Aerospace

- Automotive engines

- Precision assemblies

3.5 UNC (Unified National Coarse Thread)

- Angle: 60°

- Pitch: Coarse (lower TPI)

- Strength: Less vibration resistance than UNF

Applications:

- General fasteners

- Construction bolts

- Machinery assembly

3.6 BSW (British Standard Whitworth)

- Angle: 55°

- Form: Rounded crests and roots

- Oldest standard thread

Applications:

- Vintage British cars

- Railway and shipbuilding

- Legacy machines

3.7 ACME Thread

- Angle: 29°

- Form: Trapezoidal

- Strength: High load-carrying capacity

Applications:

- Lead screws (lathes, milling machines)

- Jacks, clamps, vises

- Industrial presses

3.8 Buttress Thread

- Angle: 45° (one side) / 7° (other side)

- Form: Asymmetrical trapezoidal

Applications:

- Heavy presses

- Screw jacks

- Artillery and tank parts

3.9 Square Thread

- Angle: 0°

- Form: Perfect square profile

Applications:

- Power transmission

- Screw jacks

- High-efficiency lead screws

3.10 Knuckle Thread

- Form: Rounded crests and roots

- Strength: Low precision, high durability

Applications:

- Bottle caps

- Light bulbs

- Railway couplings

3.11 ISO Metric Threads

- Standard: ISO 68, ISO 261

- Angle: 60°

- Type: Coarse & Fine pitches

- Global Standard

Applications:

- Global fasteners

- Manufacturing

- Automotive

3.12 Dryseal NPTF (National Pipe Taper Fuel)

- Angle: 60°

- Taper: Same as NPT (1:16)

- Feature: Creates metal-to-metal seal (no sealant needed)

Applications:

- Fuel lines

- High-pressure gas pipelines

- Hydraulic fittings

4. Comparative Table of Thread Types

| Thread Type | Standard | Angle | Taper/Parallel | Sealing Method | Application |

|---|---|---|---|---|---|

| NPT | ANSI B1.20.1 | 60° | Tapered | Sealant required | Plumbing, oil & gas |

| BSPT | ISO 7 / BS 21 | 55° | Tapered | Sealant required | Water, fire, gas |

| BSPP | ISO 228 | 55° | Parallel | O-ring/washer | Hydraulics |

| UNF | ANSI B1.1 | 60° | Parallel | Tight fit | Aerospace, automotive |

| UNC | ANSI B1.1 | 60° | Parallel | Tight fit | General fastening |

| BSW | BS 84 | 55° | Parallel | Tight fit | Legacy machinery |

| ACME | ANSI B1.5 | 29° | Parallel | Tight fit | Power screws |

| Buttress | Special | 45°/7° | Parallel | Tight fit | Heavy load |

| Square | Special | 0° | Parallel | Tight fit | Jacks, presses |

| Knuckle | DIN 405 | Rounded | Parallel | Tight fit | Bottles, bulbs |

| Metric ISO | ISO 68/261 | 60° | Parallel | Tight fit | Global fasteners |

| NPTF | ANSI B1.20.3 | 60° | Tapered | Dryseal | Fuel lines |

5. Common Mistakes in Thread Selection

- Mixing NPT and BSPT—Different angles (60° vs 55°) → leaks.

- Using UNF where UNC is required—fine threads strip more easily in soft materials.

- Assuming metric and imperial threads are interchangeable—never true.

- Ignoring taper—Parallel threads need gaskets; tapered threads may not.

6. How to Choose the Right Thread

- For sealing pipes, use NPT, BSPT, or NPTF.

- For precision fastening, use UNF or metric fine.

- For general fastening, use UNC or metric coarse.

- For heavy load & motion, use ACME, square, or buttress.

- For consumer products, use Knuckle.

7. Conclusion

Threads may seem small, but they are critical to the safety, reliability, and performance of machines, pipelines, and structures. Each type—whether it’s NPT for pipes, UNF for aerospace, or ACME for power transmission—is designed with a specific geometry and purpose.

Understanding thread angles, pitch, and applications helps engineers avoid costly mistakes, ensures compatibility, and guarantees performance.

Next time you pick up a bolt or connect a pipe, remember: it’s not just a spiral groove—it’s centuries of engineering evolution that keeps our world together.

Questions (FAQ) on Types of Threads

Q1. What are the different types of threads used in engineering?

The most common types of threads are NPT, BSPT, BSPP, UNF, UNC, BSW, ACME, Buttress, Square, Knuckle, ISO Metric, and NPTF. Each has a specific angle, pitch, and application depending on industry needs.

Q2. What is the difference between NPT and BSPT threads?

NPT threads have a 60° thread angle, while BSPT threads have a 55° Whitworth angle. NPT is common in the U.S., while BSPT is widely used in Europe and Asia. They are not interchangeable due to the angle difference.

Q3. Which type of thread is best for high-pressure sealing?

For high-pressure sealing, NPTF (Dryseal) threads are best because they form a metal-to-metal seal without the need for tape or sealant. BSPT and NPT also work but usually require sealant.

Q4. What is the difference between UNF and UNC threads?

- UNF (Unified Fine Thread) → More threads per inch, stronger hold, used in aerospace and automotive precision parts.

- UNC (Unified Coarse Thread) → Fewer threads per inch, easier to assemble, used in construction and general fastening.

Q5. Why are ACME threads used in machines?

ACME threads have a 29° trapezoidal profile, which provides excellent strength and load-carrying capacity. They are widely used in lathes, milling machines, jacks, and vises for power transmission.

Q6. Can I use BSPT fittings with NPT fittings?

No. BSPT and NPT threads are not compatible because they have different thread angles (55° vs 60°). Using them together will cause leaks and fitting damage.

Q7. Which type of thread is most common worldwide?

The ISO metric thread is the most widely used thread standard globally. It has a 60° angle and comes in coarse and fine pitch versions. It is used in almost all industries for nuts, bolts, and fasteners.

Q8. What are square threads used for?

Square threads are used for power transmission in applications such as screw jacks, presses, and lifting devices. They are very efficient but harder to manufacture compared to ACME threads.

Q9. What type of thread is used in bottle caps and light bulbs?

Knuckle threads are used for bottle caps, railway couplings, and light bulbs. They have a rounded profile that makes them durable and resistant to wear.

Q10. How do I select the right type of thread for my project?

To select the right type of thread, consider:

- Sealing requirement → NPT, BSPT, NPTF

- Precision fastening → UNF, Metric Fine

- General fastening → UNC, Metric Coarse

- Heavy load/motion → ACME, Buttress, Square

- Consumer products → Knuckle